Design and order custom packaging that enhances your brand identity and delivers a professional, unforgettable unboxing experience.

Luxury hexagon rigid boxes designed to elevate premium products, combining distinctive structure, strength, and high-end visual appeal.

Sturdy rigid boxes specially crafted for candle packaging.

Protect candles while enhancing shelf presence and brand value.

Space-saving collapsible boxes with a premium rigid finish.

Ideal for luxury packaging, easy storage, and cost-effective shipping.

Functional dispenser boxes for easy product access and display.

Perfect for retail packaging that boosts visibility and convenience.

High-quality CBD packaging designed for safety and compliance. Custom printed boxes that enhance trust, branding, and shelf appeal.

Food-grade cereal boxes with eye-catching custom designs.

Keep products fresh while maximizing brand recognition on shelves.

Retail display boxes designed to attract customer attention.

Increase product visibility and drive in-store sales effectively.

Eco-friendly hemp packaging made for sustainable brands.

Perfect for natural products with a clean, modern presentation.

Secure and stylish packaging for vape and e-liquid products.

Designed to meet retail standards and enhance brand identity.

Protective packaging for bath bombs with premium aesthetics.

Keeps products safe while elevating the unboxing experience.

Luxury packaging solutions for beauty and cosmetic products.

Designed to enhance brand image and customer appeal.

Custom soap packaging that combines protection and style.

Ideal for handmade, organic, and retail soap brands.

Durable and child-safe packaging for toys and games.

Bright designs that improve shelf appeal and brand trust.

Food-safe bakery boxes for cakes, pastries, and desserts.

Perfect for maintaining freshness and professional presentation.

Grease-resistant burger boxes for fast food packaging.

Designed for durability, hygiene, and strong brand visibility.

We tailor size, shape, material, color, finish, and structural features to match your branding

Advanced offset, UV, embossing, foil stamping, and spot UV techniques for a premium look.

Recyclable, biodegradable, paper materials to support sustainable business practices.

State-of-the-art production lines and a reliable supply chain to ensure timely delivery worldwide.

High-quality packaging at cost-effective rates to maximize your profit margins.

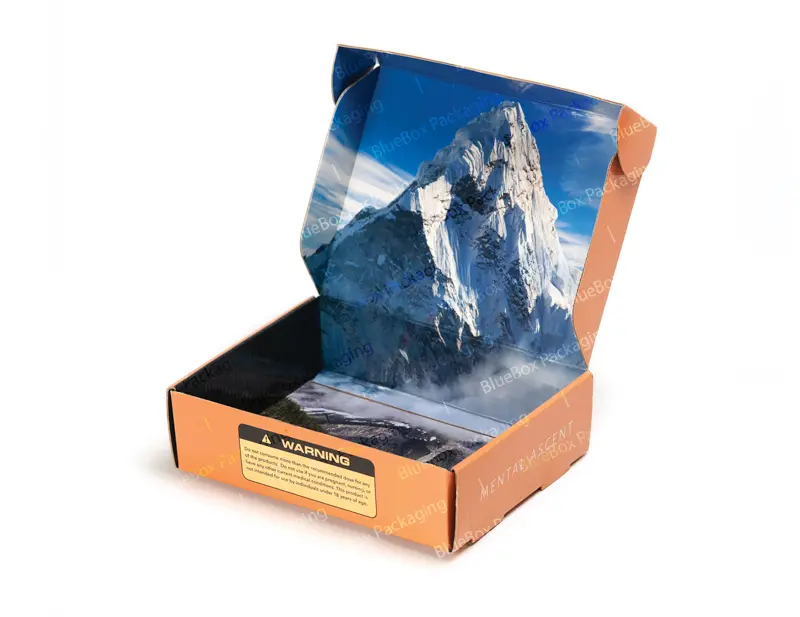

Elevate your packaging with custom printed boxes designed to reflect your unique brand identity. Whether you’re shipping products across the globe or showcasing them on store shelves, our tailor-made boxes combine style, durability, and precision to make a lasting impression. Whatever your industry, we create packaging that not only protects your products but also tells your brand’s story turning every unboxing into a memorable experience.

Transform ordinary packaging into an unforgettable unboxing experience. Our custom boxes combine premium materials, elegant finishes, and exquisite design to create packaging worthy of your brand. Every detail is crafted to impress, turning every delivery into a moment your customers will remember.

Yes, you can get a sample before placing an order, but it is only available on demand and you have to pay for it.

You may place a minimum order of 100 boxes

No, we do not operate on weekends or holidays.

We deliver your order within 7 – 12 working days.

Place your order by filling the quotation form so that one of our representatives may get in touch with you.

If you want to avail discounts and packages then follow our social media accounts and stay tuned for the next discounts and packages!

As box quantities increase, pricing becomes more cost-efficient, so the more you order, the lower your per-unit price will be. The price of your box is generally determined by its dimensions, box style, ink coverage, box material, and quantity. Among the leading custom box manufacturers, PBP offers competitive prices on custom printed boxes. We can beat any verified quote you find anywhere. It’s important to us to maintain a reputation as one of the most cost-effective providers of custom packaging printing.

Yes, an instant quote is provided once you select the size, material, and quantity of your order.